How our method evolved

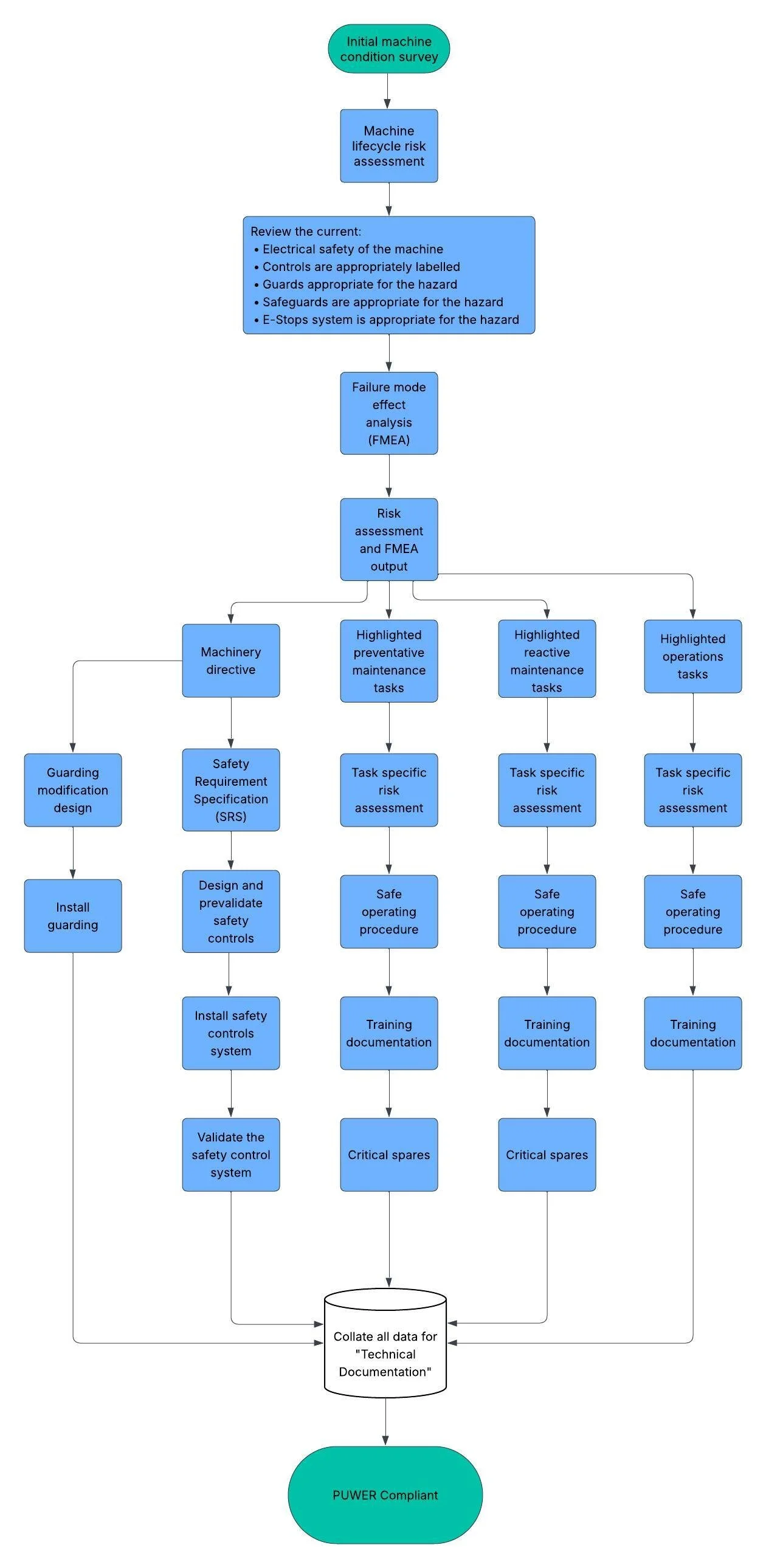

What began as a response to a serious incident became a complete, proactive method for machine safety and reliability. After implementing task-specific risk assessments and detailed structured planning, we aligned boiler operations with BG01 and BG04 — achieving 12 months of stable performance. That success led us deeper into PUWER and ISO 12100. We began applying risk assessment pre-planning for larger tasks — not just standard preventative maintenance works — and built full 12100-aligned assessments that highlighted weaknesses in safeguards. We extended this to FMEAs from the risk assessment, this highlighted reactive task risk coverage, required preventative maintenance and task based risk assessment and SOP gaps, and even compiled machine-specific critical spares lists to support long-term reliability. The result is a system that doesn’t just meet compliance — it enables it, sustains it, and uses it to drive performance.

Book a free machine safety review

Send us a picture of the machine you want to discuss and a brief description of any concerns and we’ll arrange a call lasting upto 30 minutes.

We’ll go through what’s already in place, where the gaps may be and what your next steps are.

No obligation, just advice. reach out at info@verificare.co.uk